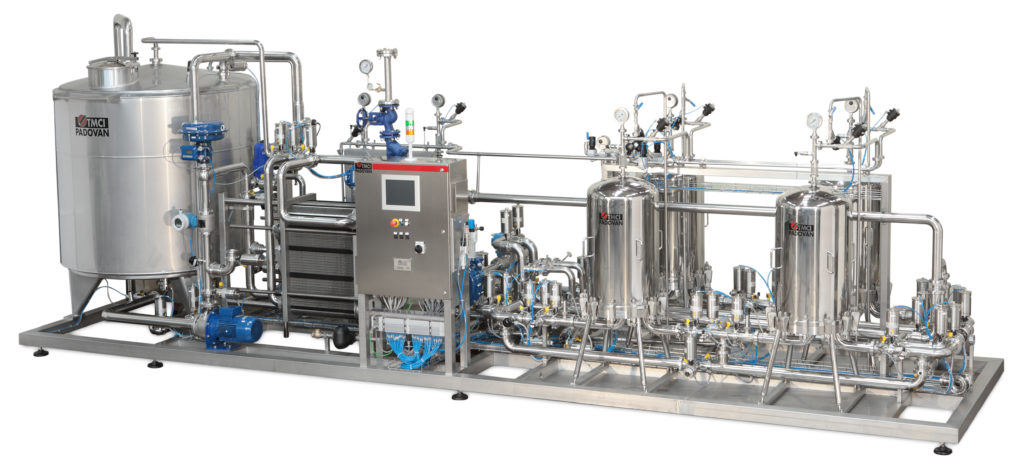

Microfiltration for wine, grape juice and distillates

DESCRIPTION:

The microfiltration plants, from 10 to 500 hl/h, automatic or manual, are made in AISI 316 Stainless Steel and they strictly observe the most rigid hygiene criteria. Sets of valves permit to exclude each housing allowing the filtration while the other bank is in washing procedure, in order to perform the CIP and thermal sterilization operation, they are provided with a 1 or 2-stage filtration lines for the service water.

The pre-set values of the plant, which are periodically registered, are constantly monitored in automatic way and if they do not comply with the requirements, the operator is immediately warned by an acoustic device. The PLC, in the automatic versions, through a user-friendly HMI, controls all the process phases and allows the interfacing with other devices inside the production site.

Competitive advantages

- Barriers with mix-proof valves between the filtration and the washing housings to prevent any leakage of chemical solutions with the product filtered;

- Washing circuits specifically studied for a 100% sanitization;

- Automatic control of filters swap without operator intervention;

- Total recovery of the product inside the plant.